| 1. | Substrate surface treatment |

| In case substrate surface treatment is poor, popping and peeling after heating occur due to the expansion and shrinkage of substrate. | |

| Please follow the Spray specification and strictly keep the level in the Substrate surface treatment table. | |

| (See the Substrate surface treatment table) | |

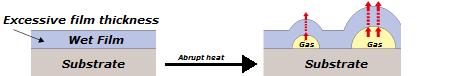

| 2. | Film thickness |

| Apply specified DFT written in this catalog. | |

| In case film thickness is too high (2 times higher than std film thickness), it becomes the cause of popping and peeling. | |

| Especially top coat silver color is easy to cause popping due to the tight film when film thickness is high. | |

| 3. | Initial heating |

| Initial heating should be implemented gradually. | |

| In case rapid heating is charged, remained solvent in wet film and volatile matters generated from curing process become gas then it causes popping and becomes the risk of peeling. (Std. for temperature rising : max 200℃/hour) | |

| We recommend a rapid heating type, HN-600, for abrupt temperature rising condition. |